What are the printing techniques or methods of jeans?

1. Digital printing:

It refers to the use of inkjet or reactive dyes to print computer-processed patterns on denim fabrics to form vivid artistic patterns. The formation method is very different from the traditional flat screen and rotary screen printing method. Modern denim printing patterns pay more attention to individualization and customized production. Traditional floral and animal patterns have gradually fallen out of focus. People are more inclined to light psychedelic and abstract patterns. Such rapidly changing popular elements have caused unpredictable market changes. However, digital printing satisfies the small-volume, multi-variable production model, which makes denim printed apparel a surprising success.

2. Laser printing:

It refers to the pattern effect formed by burning the yarn and vaporized dye on the surface of denim fabric through computer image processing. Denim fabrics are mostly used for the treatment of cat whiskers, monkeys, tearing, distressing, washing and other decorative effects. Compared with the traditional handmade production such as spraying potassium permanganate, laser production reduces the discharge of water pollution and the cumbersome processing process Link. The laser printing pattern is clear, and it can accurately print all kinds of artistic style patterns on the fabric. Compared with the plane and two-dimensional patterns formed by traditional printing, the laser-forming pattern has a stronger three-dimensional effect and a more varied style; but its working principle The limitations of the result can only form a dark and light denim background effect. Its advantages are faster than traditional printed denim, simple operation, high efficiency and environmental protection.

3. Hand-painted:

The use of textile dyes or acrylic paints to create paintings on denim clothing is also an expression of the personality of young people today. Mainly according to the application of brushes or different tools, use outline, flat coating, splashing and other brush strokes to draw decorative effects on the finished denim clothing, forming a unique denim clothing. The penetration of textile dyes is better than that of acrylic paints, and the touch feeling on the fabric is better after drying. Hand-painted denim garments can be directly painted by hand after finishing, avoiding the damage of the color vividness of the pattern after finishing.

4. Discharge and engraving:

Discharge engraving refers to the addition of engraving powder or a strong bleaching agent that destroys the background color on the surface of the dyed denim fabric, and then printing on the screen with a discharging printing paste, then drying, steaming, and washing. The effect of blue background and white flowers produced by other processes. When the bleaching agent does not react with the background color, adding other colors to the dye can print a color pattern on the indigo cloth. This printing method is called color discharge.

5. Paint overprint:

Refers to the use of color pastes with good proportions and the use of rotary screens or flat screens to print patterns on denim fabrics. The coating has good coverage, the surface of the fabric is flat, and it is not absorbed by the fabric. It is applied to the parts of denim jacket with less friction. Among them, there are more full-page overprints on the back. It is not suitable for application on thin, soft or fluffy fabrics.

6. Transfer printing:

Transfer printing refers to printing dispersible dyes on a special paper surface or a reusable substrate, using different methods such as hot pressing to transfer patterns to denim fabrics.

7. Flocking printing:

After printing the adhesive paste of the desired pattern shape on the denim fabric, electrostatic flocking is carried out, and finally a post-processing is carried out. This type of printing requires a strong adhesive to ensure a firm bond between the short suede surface and the denim fabric. Denim clothes give people the feeling of civilians with strong colors, which are not suitable for heavy makeup, but the flocking printing technique is mostly used in high-end denim clothes, and the patterns are mostly retro European style and rattan flowers. Its advantages: the fabric has a strong sense of three-dimensional concave and convex, the pattern has a stepped sense of layering, and the hand feels soft. Disadvantages are: the production volume is small, it is not suitable for scrubbing and rubbing excessively, and the flowers should not be complicated and excessively emphasized when designing patterns.

8. Bad print:

On the basis of the traditional burnt-out process, the burnt-out pulp is used to rotten cotton on the denim fabric, and then it is finished after washing and so on to form an alternative style denim dress with a three-dimensional effect of de-threading. The white weft yarns of the burnt-out part are scattered, and the warp and weft yarns of the pattern part are not damaged to form a three-dimensional carved plant pattern. This kind of printing design technique has destructive aesthetics and is not suitable for application on knitted denim, that is, denim fabric woven by loops.

9. Foam printing:

A printing paste composed of a thermoplastic resin and a foaming agent is printed on the denim fabric, and a three-dimensional embossed pattern is formed after the high-temperature vapor evaporation bubble treatment. The edge of the denim fabric pattern of foam printing is more difficult to handle, and it is mostly used in cartoon or letter patterns.

10. Traditional printing:

Traditional printing also refers to printing and dyeing, which refers to the general term for the process of dyeing, printing, finishing, and washing. Sometimes called dyeing and finishing, it is a processing method of textiles.

11. Manual printing:

There are letterpress printing and hollow printing which are commonly used in hand printing. Letterpress printing refers to the use of stencils to engrave patterns, and the use of yin and yang surfaces to rub on denim fabrics to form graphics. Hollow board printing is also called stencil printing, which refers to the use of stencils of different materials to engrave hollow patterns, and scratch and paint the hollowed areas on the fabric.

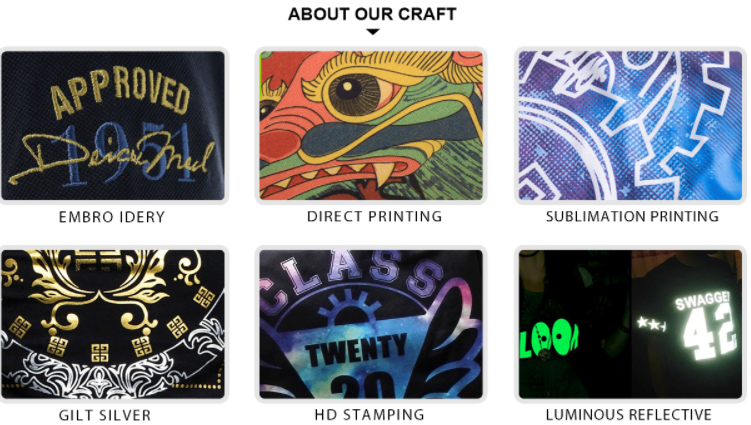

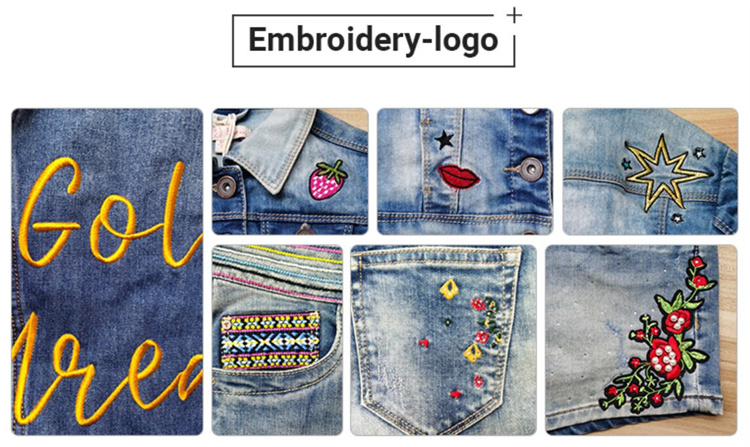

Custom Artwork: Embroidery and Printing, also Adding accessories.

Custom Logo: Embroidery , cut&sew applique, high density printing, rubber printing, heat transfer , embroidery patch , 3D printing, litter solid embroidery.